About Us

PennEngineering®: Your success is our tradition

After more than 80 years in this industry, we know that innovation takes time – and that you need to make the most of it. We understand your vision and provide the reliable fastening and component solutions you need to get to market sooner. Our leading PennEngineering® brands are here for your eMobility application needs.

Innovation, full speed ahead

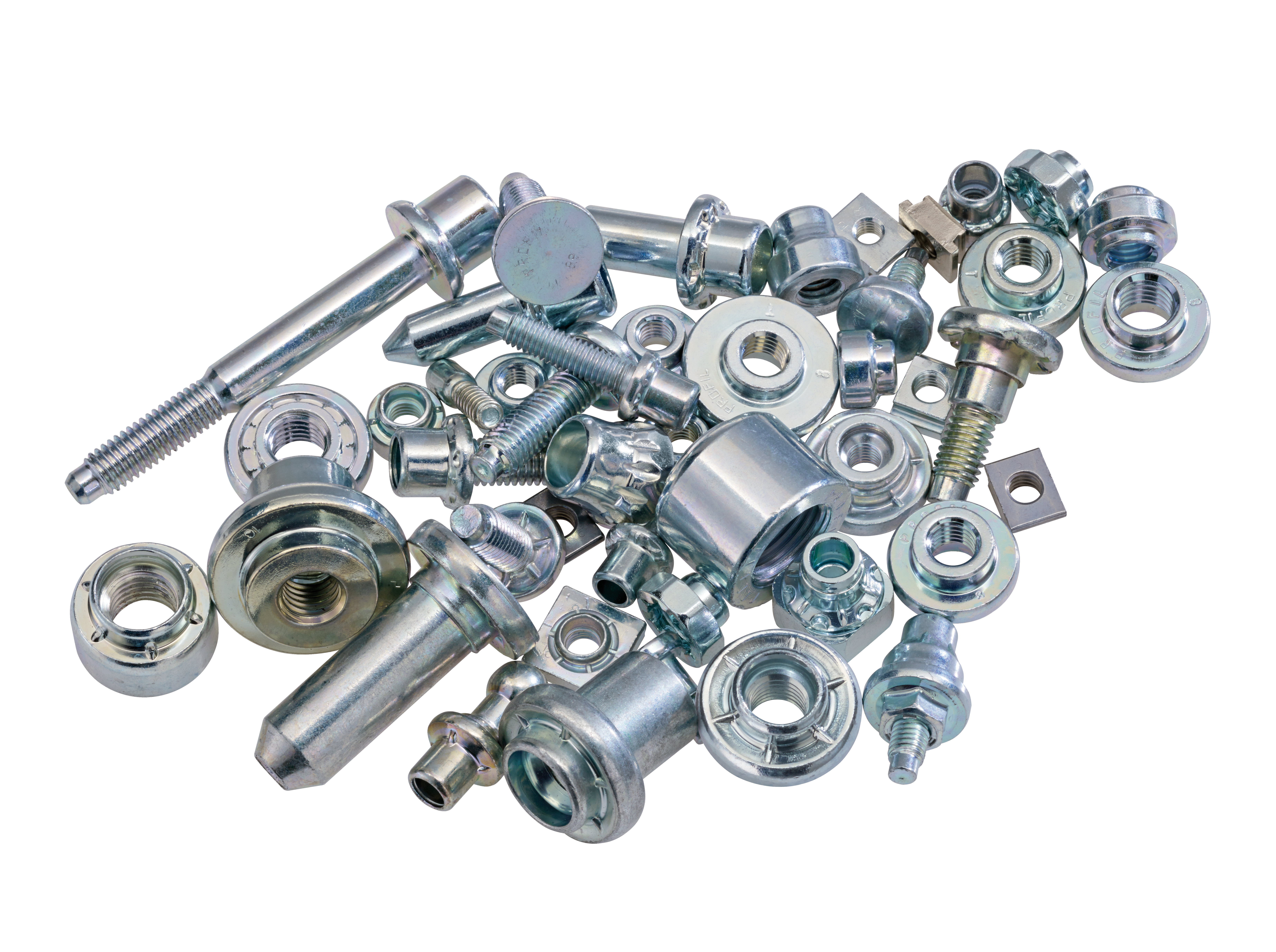

PEM®

PEM’s® commitment is to create lasting connections fueled by the belief that small components have a powerful impact. From heavy-duty fastening solutions for structural systems to precision-engineered micro fasteners and current carrying fasteners for automotive electronics, PEM’s® expansive portfolio of innovative products for the automotive industry is unmatched.

Learn more about PEM®

PROFIL®

PROFIL® is the world’s premier global manufacturer of mechanically attached fasteners (MAF) – an alternative to traditional weld fasteners – for the automotive industry. For decades, PROFIL® has partnered with the world’s leading automotive OEMs to develop and engineer high-integrity, cost-effective joining solutions for a wide range of demanding vehicle applications.

Sherex

Sherex Fastening Solutions is an innovative manufacturer of fasteners for a variety of industries. Sherex product lines of rivet nuts, clinch nuts, threaded inserts, Disc-Lock® and TEC Series® wedge-locking products, and fastener installation systems are used by many Fortune 500 OEMs to strengthen attachment points while decreasing assembly times and waste.

Heyco®

With over 90 years of experience in the design and manufacture of molded wire protection products and stamped electrical components, Heyco® understands what it takes to meet demanding customer requirements. We employ highly qualified professionals, use advanced technology, and produce high-quality products in the necessary quantities for our customers’ applications.

Choosing sustainability in eMobility

At PennEngineering®, we’re taking an aggressive and proactive approach to reduce and eliminate the impact of our business on the environment. We’re committed to:

- Reducing welding power by using mechanical bolted joints and rivets

- Replacing the need to weld to help avoid splatter and emissions from high temperatures

- Improving assembly and disassembly for easier recycling of parts

- Helping customers reduce their carbon footprint by manufacturing parts locally