Installation

Intuitive installation that has a big impact on the bottom line

Fasteners may represent a small portion of your component costs, but they can make major in-roads to your total build costs because of how quick and easy they are to install. Whether you need installation systems for in-die, robot cell, or manual, you can expect best-in-class equipment with low-complexity.

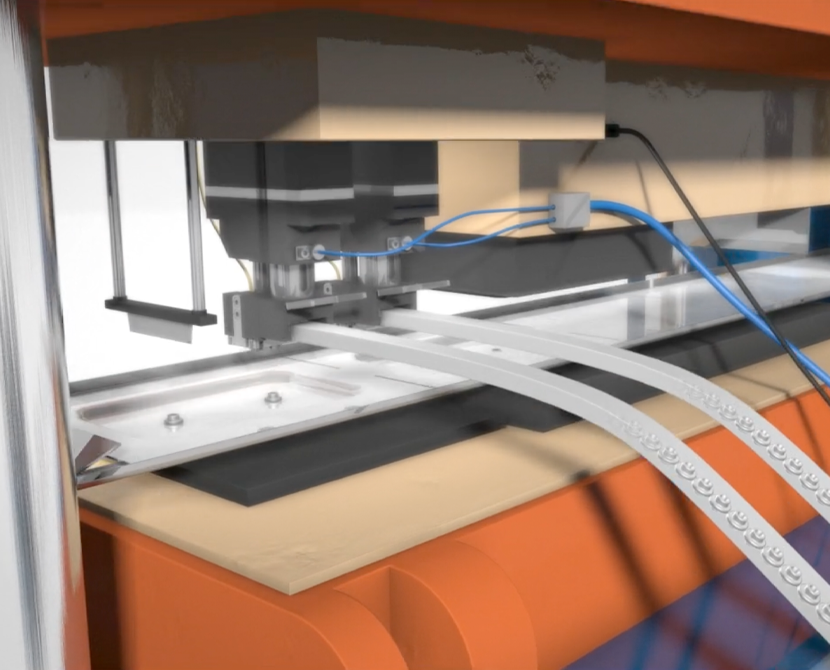

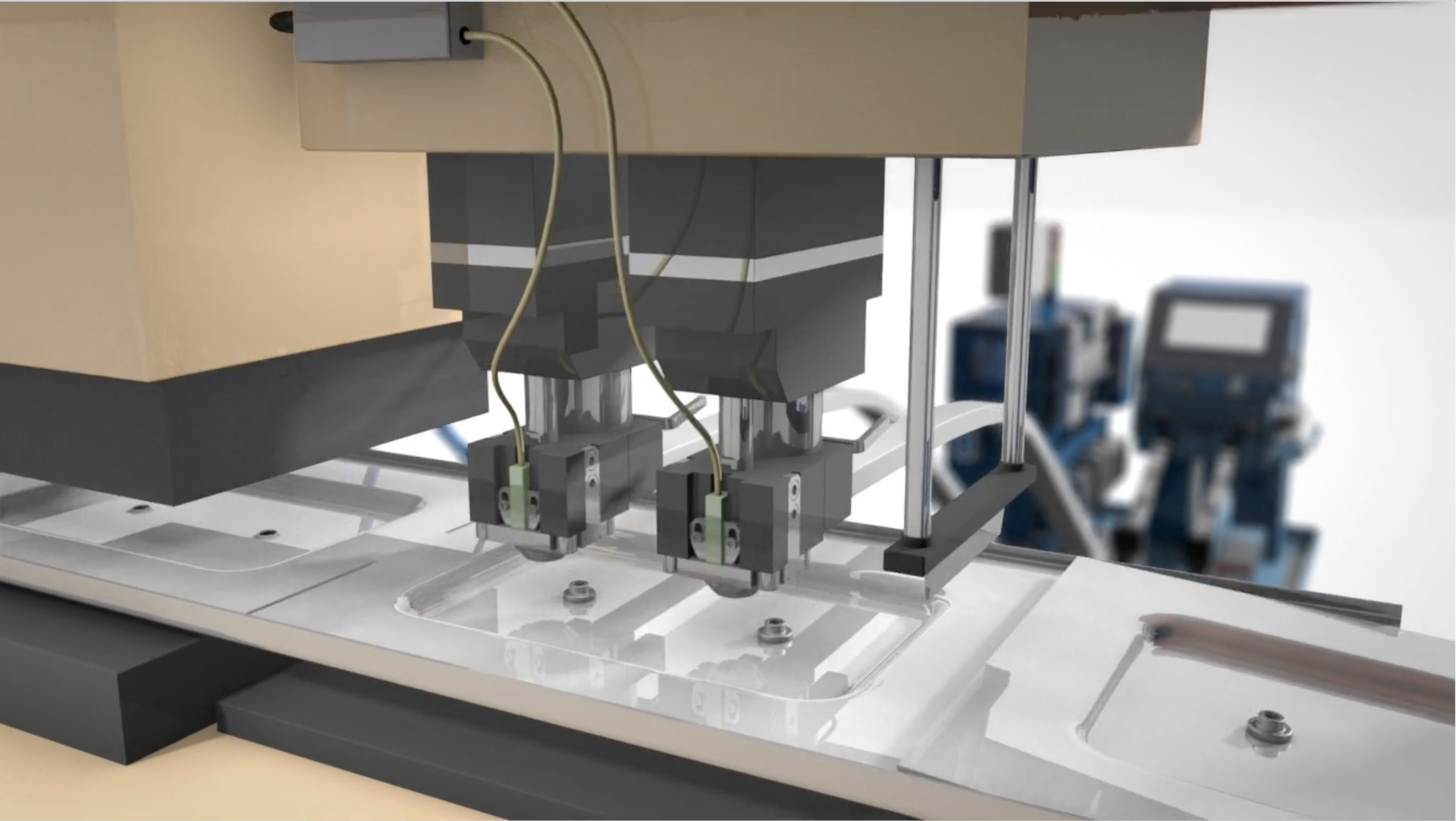

In-Die

PennEngineering’s in-die fastener installation system enables you to install a high volume of fasteners automatically, efficiently, and accurately in the stamping process itself. This eliminates secondary operations, which means reduced lead times and fewer labor and application costs.

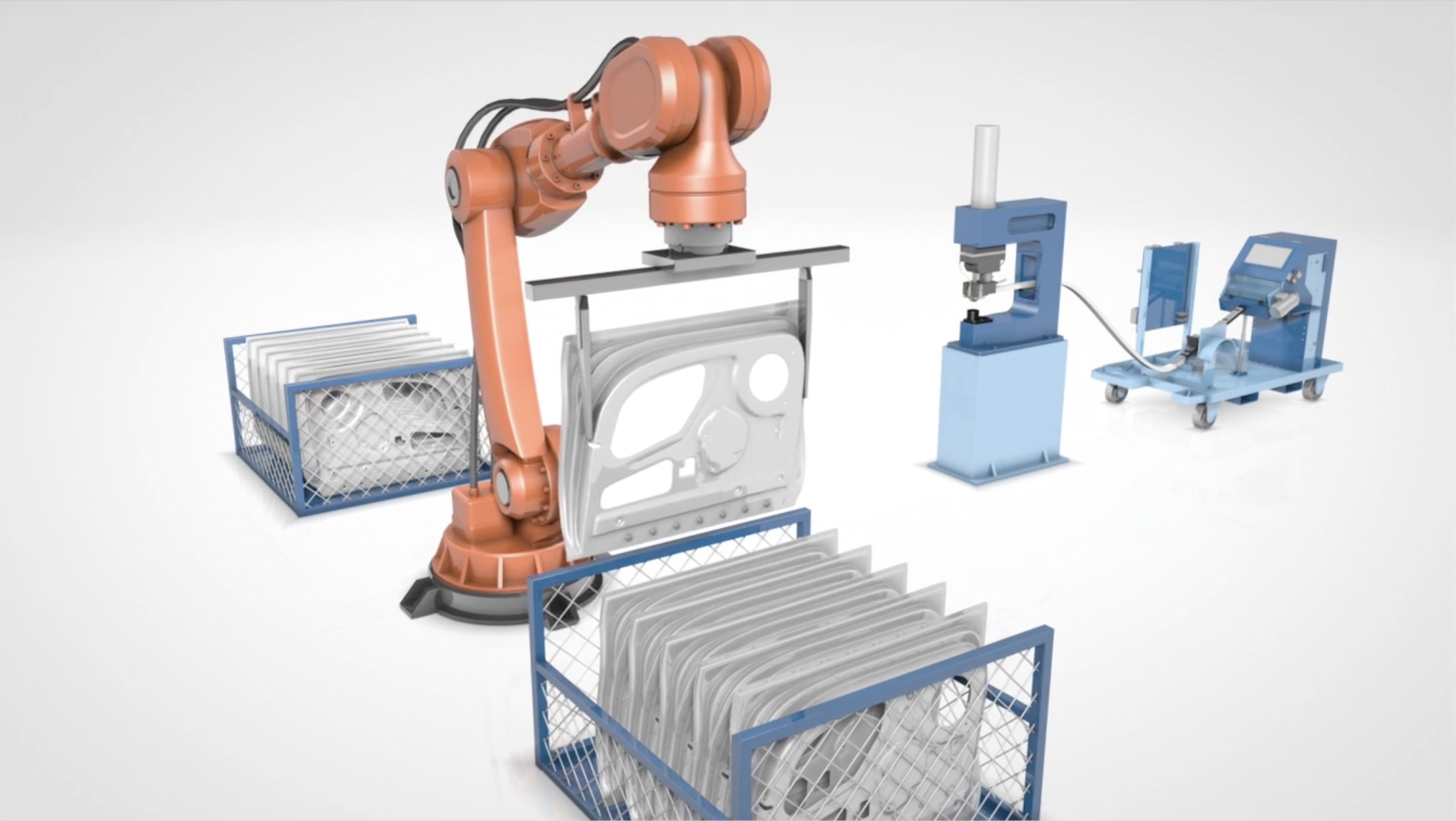

Robot Cell

Our installation system for medium volumes consists of robot-handling software integrated with the stamping press. This allows our system to integrate with robot assembly equipment which seamlessly performs the fastener installation, providing the efficiency and accuracy needed for quality production.

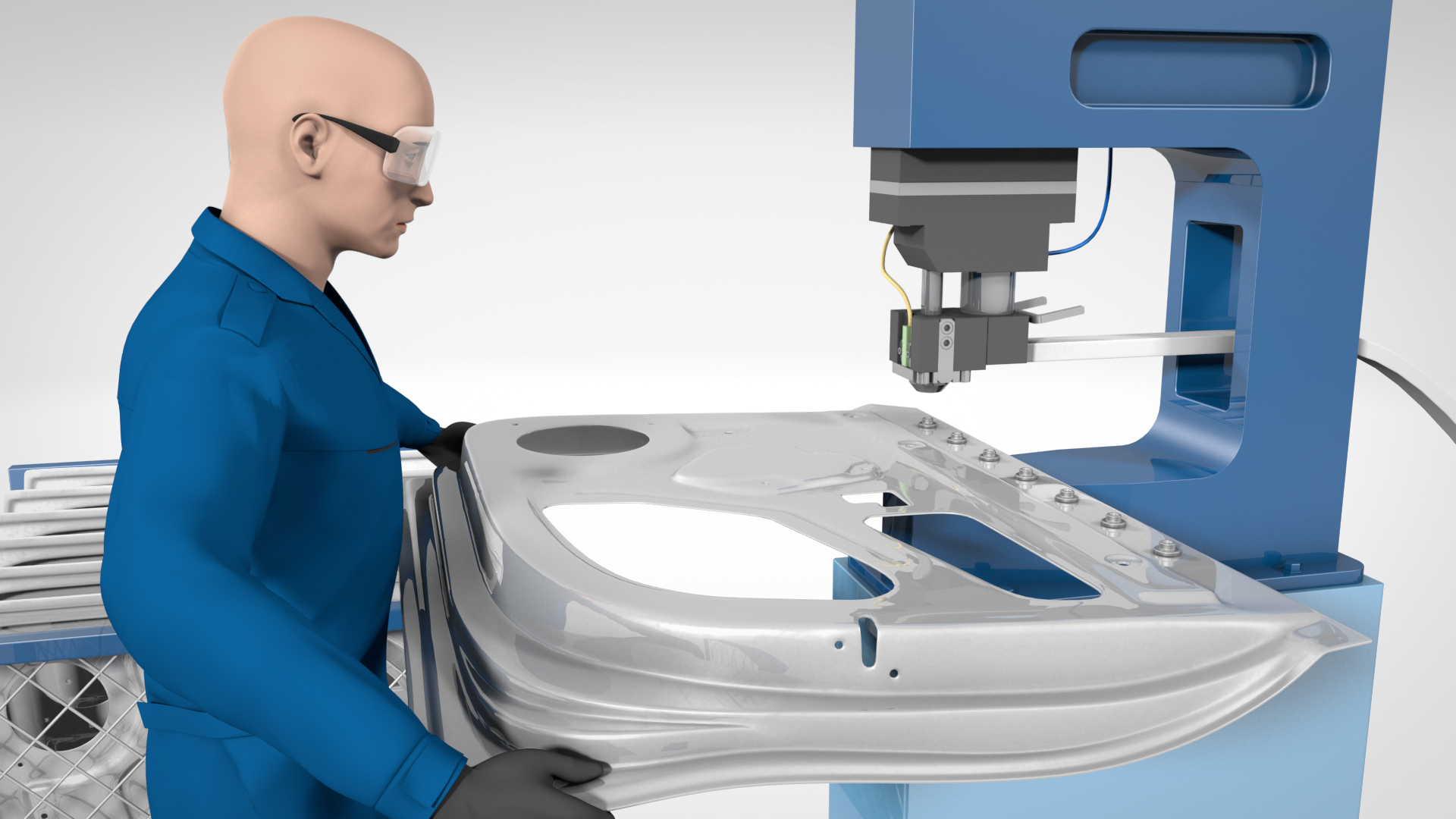

Manual

For lower volumes, you may need a manual fastener installation process. In this case, a person takes the place of the robot and carefully feeds the panel into the user-friendly c-frame press to install the mechanically attached fasteners.

Haeger®

Our Haeger® semi-automated fastener installation equipment was designed to install PEM® fasteners – a total system solution that gets installation right the first time. Reach optimal production performance and reduce the risk of human error with precise, consistent, and repeatable installations.

Ready to get started?

Get ahead. Talk to an engineer.

Discover exceptional fastening and electrical conductivity solutions for everything eMobility. Together, we can take your build to a whole new level – partnering to make application assembly quicker and more cost-efficient.