Industry Applications

Explore our eMobility solutions for your industry application

Find the right combination of proven eMobility fasteners and cable management solutions to meet your industry application needs – whether it’s getting power to the motor, protecting against ingress and heat dissipation, providing streamlined electrical conductivity, or ensuring a high-quality and reliable EV charging experience.

Automotive Electronics

You can cover all electrical components of a vehicle with our conducting and non-conducting mechanical connectors and technically proven electrical fasteners. This encompasses aspects of power distribution, cleanliness, secure connections, space optimization, weight reduction, labor efficiency, and material selection. Meeting these challenges is essential for creating safe, reliable, and efficient electrical components in modern vehicles.

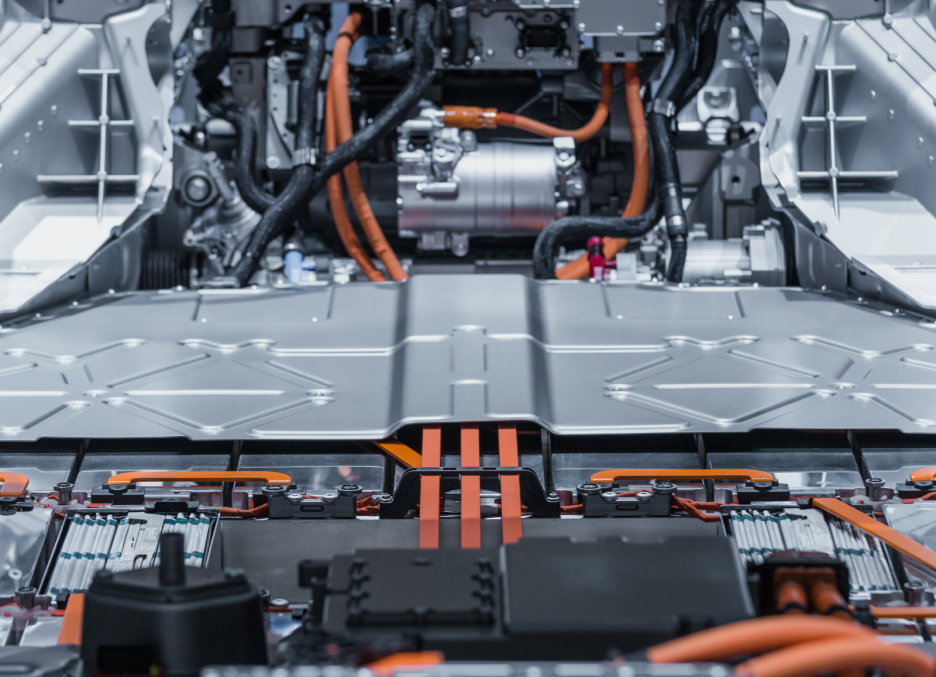

EV Battery Trays

Design engineers face several challenges when designing every aspect of the EV battery, including achieving a low-profile design, ensuring water tightness, managing weight for efficiency, and maintaining the necessary strength to support the battery's weight and ensure safety. Balancing these factors with the right battery components is essential for creating effective and reliable batteries in electric vehicles.

Charging

It’s essential to strike the right balance between cost-effectiveness and reliability, as charging stations are the backbone of the EV charging infrastructure. Both residential and commercial charging stations need to withstand high voltage and amperage levels to deliver fast and efficient charging, maintain consistent performance across thermal cycles and environmental conditions, and stand up to rigorous daily use while minimizing breakdowns and maintenance. Let us help you focus on repairability and replaceable components to reduce downtime and maintenance costs.

Battery Energy Storage Systems (BESS)

Together, we can create the right technical solutions for every component of both residential and commercial battery storage systems. Modularity and serviceability, facilitated by specialized fasteners, are crucial aspects of BESS design. Additionally, cost implications associated with system failure are significant driving factors in designing BESS solutions that are robust, dependable, and easily maintainable.

Two- and Three-Wheeled Vehicles

Overcome the unique challenges that come with two- and three-wheeled vehicles, including the need to save space and weight – which demands small, lightweight, and rugged fasteners that can fit within tight frames. Lightweighting often leads to the use of brittle castings, making them challenging to work with, especially when threading is required. Our IP-rated fastener solutions, however, help to ensure corrosion resistance (even in demanding environments) and make assembly easier and less costly.

Gain a competitive edge in eMobility

Optimize application performance, better determine safety and compliance, and explore opportunities for innovation with PennEngineering’s value added services.

Application Engineering

- Application Review

- Custom Design/Product Development

- Customer Drawings

- Catalog Samples

- 3D Models

- Prototype Development Center

PEMedge® Testing Services

- FEA Analysis

- Mechanical Testing

- Tensile and Compression Strength

- Micro Hardness

- Fastener Joint Cross-Sectioning

- Corrosion and Plating Testing

Teardown Service

- Complete Product Disassembly

- Assembly Structure Assessment

- Identify Alternative Fastening Solutions

- Alternative Fastener Replacement/Testing

- Teardown Report

- Identify Efficiencies/ Implementation Plan

FastenerClass®

- Free Customized Training Sessions from Global Experts

- Live, Web-based, and Pre-recorded Training Options Available

Standard Classes Include:

- Theory, Best Practices, Application Exploration

- Intro to Self Clinch Theory

- Proper Fasteners for Stainless Steel Panels